Craftsmanship

Traditional methods / Finest materials / Handmade

Manual shoe-making has not changed much over the past centuries. I prepare my shoes using special shoemaker tools and hundreds of meticulous operations. Starting from the selection of finest calfskin and different top quality leathers sourced from the best tanneries to the polishing of already finished shoes. Each activity in the production process is performed to the highest level possible.

To explain this better, I would like to walk you through my bespoke process:

1. Making of shoes last

The he first step would be to meet the client and take the measurements. Once I have the measurements, a last will be sculpted from wood specifically for the individual’s foot. After that I will start working on the design.

2. Design and cutting

The cut of the shoe uppers is done exclusively by hand, to ensure that only the best leather is chosen for a specific model.

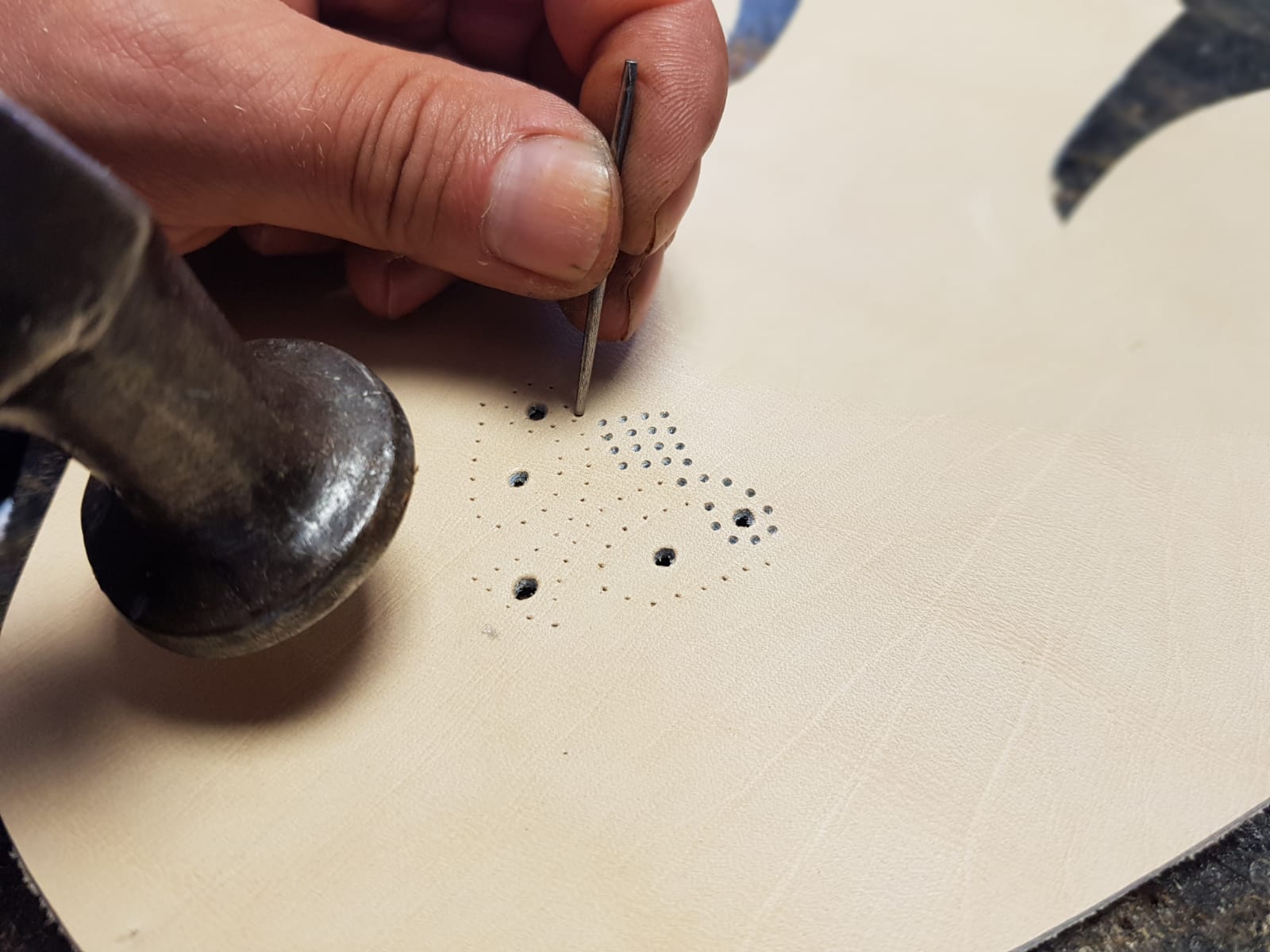

3. Shoe uppers sewing

Each pair of uppers is crafted from beginning to end with great attention to detail by myself. This guarantee a flawless, precise and accurate upper.

4. Lasting

The uppers are stretched over the lasts. This is done by hand with pliers, hammer and nails, just like the handmade tradition methods.

5. Hand stitching the welt and the soles

Stitching the welt and soles is a very specific task, crucial in making the product unmistakably unique due to being stitched by hand using hand waxed linen thread.

6. Finishing of a pair of shoes

Once shoes have dried, they are ironed, impregnated and shined using hot wax.The tools used are heated to high temperatures. Once this is done, the shoes are left on the last for a few days until they are completely dry.

7. Polishing

All my shoes are polished by using only the best creams. The final result is a clean shoe that shines naturally.